LHJ Superfine Impact Mill

basic information

Product description

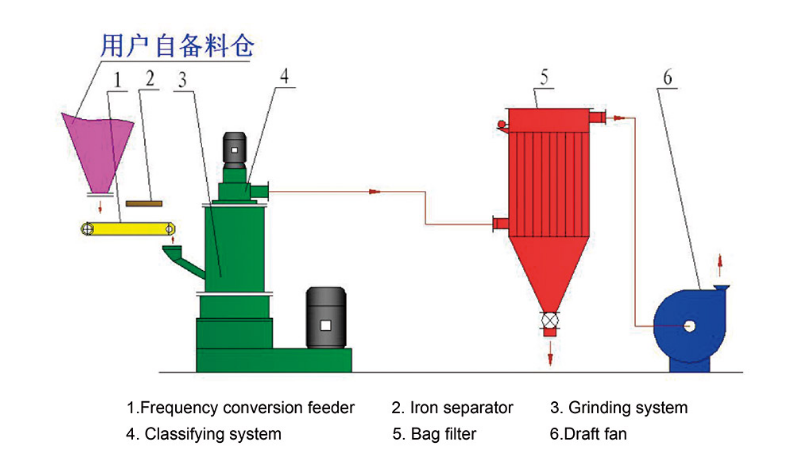

The material is transported to the crushing chamber of the host by the feeding device, and the material and the high-speed rotating device and particles impact, collide, rub, shear, and squeeze each other to achieve crushing. The crushed material is separated into coarse and fine powder through the classification wheel. The coarse powder flows into the crushing chamber and is ground again, and the purified gas is discharged by the induced draft fan.

Performance advantages

LHJ superfine impact mill is a new type of mechanical pulverization equipment independently developed by our company. Its comprehensive performance index has reached the world advanced level, and it has become the first choice for many ultrafine powder processing.

1. Low energy consumption: it integrates centrifugal crushing, impact crushing and squeezing crushing, which can save up to 40-50% energy than other mechanical crushers.

2. High fineness: Equipped with self-diverting grading system, product fineness ≥2500 mesh.

3. Large feeding range: the feeding granularity is ≤50mm, and the material only needs to pass the first-level roughing equipment.

4. Low abrasion: The crushed parts are made of composite wear-resistant new materials, with long service life, and no pollution when processing materials with Mohs hardness ≤5.

5. Strong mechanical stability: It can be produced for 24 hours without shutdown.

6. Full function:

It can crush needle-shaped materials to achieve a length-to-diameter ratio of 15: 1;

No temperature rise in the crushing process, suitable for the crushing of heat-sensitive materials;

It can disperse the sintered agglomerated ultra-fine materials with a granularity recovery rate of 100%;

With particle shaping function, effectively increase the packing density.

Materials that can crush fibrous tissue;

It can crush materials with high moisture content, with drying function;

It can crush materials with strong viscosity.

7. Negative pressure production, no dust pollution, excellent environment.

8. High degree of automation, strong stability and easy operation.

Flow chart

Technical Parameters

Incase any changes of products model and data,interpretation right reserved by Zhengyuan company

Appplication fields

Non-metallic mineral powder materials

Barite, wollastonite, diatomaceous earth, graphite, talc, carbon black, etc.

Chemical powder materials

Flame retardant, aluminum hydroxide, silica gel, Yuanming powder, magnesium oxide, polyacrylamine, iron oxide red, etc.

Battery powder material

Lithium iron phosphate, lithium manganate, lithium cobaltate, lithium titanate, cobalt tetraoxide, cobalt trioxide, graphite, ternary materials, etc.

Other powder materials

Medicine, food, bone meal, shell, hard nutshell, wood powder, cassava powder, food calcium, etc.

Product Project cases

The next article

LHG Roller Mill