LHF coating machine

basic information

Product description

Feed the material into the powder coating machine → drop the modification agent by pump → the material and the agent will be fully mixed together when the machine is operating at high speed; and the heat, which is generated by the high speed movement of the rotors and material, will help the agent coated on the material powder surface at the same time → finally, the finished products will be collected by the negative pressure collection system.

Performance advantages

1. Continuous operation , thus guarantee a high production capacity.

2. Working independently or working in a production line (combined with superfine grinding mills, etc.) are both possible.

3. High coating ratio; high activation index; low consumption of coating agent.

4. No material aggregation: as a result, finished products can be packaged directly.

5. Low power consumption:

–lowest power consumption could be 30 kwh/t;

–self-generated heat of the machine can be directly used for material’s surface engineering; as a result, there is no need of any other additional heating system.

6. Modification temperature can be adjusted to meet different requirements.

7. Eco-friendly: negative pressure production help to offer a dust-free production environment.

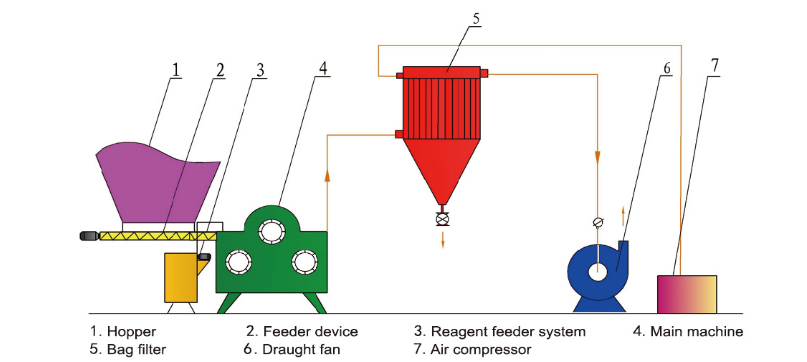

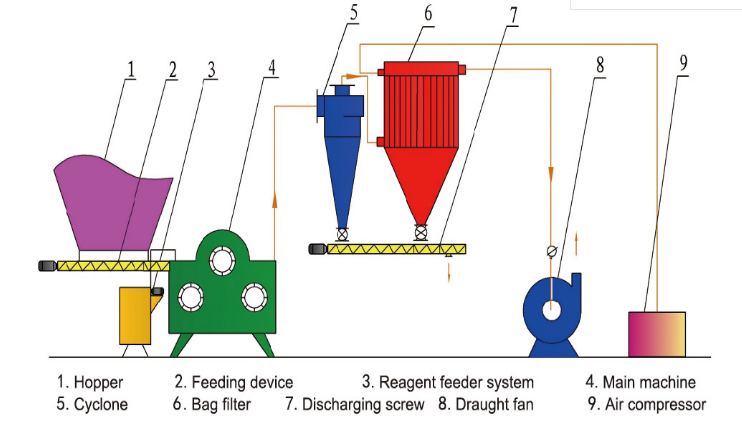

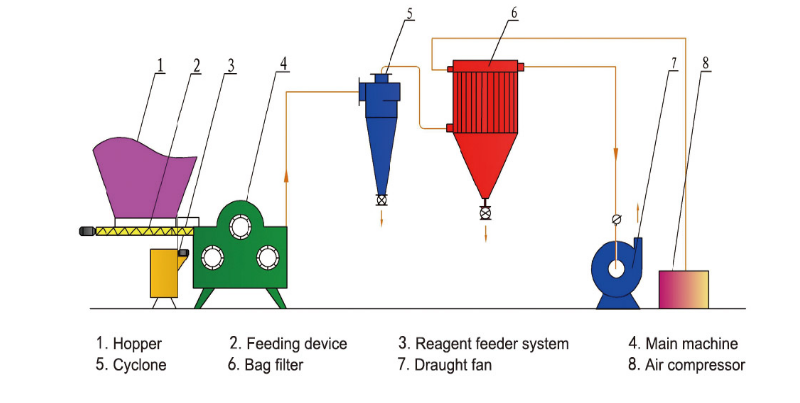

Flow chart

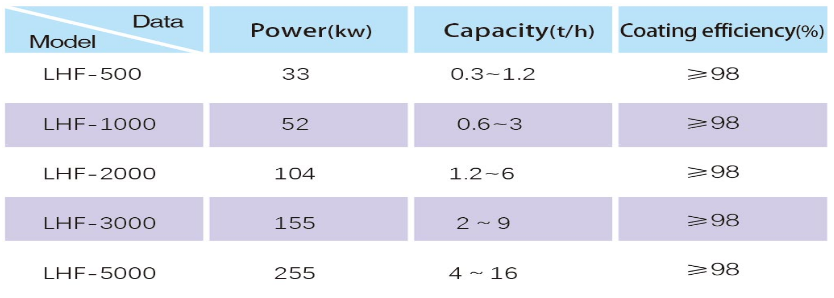

Technical Parameters

Incase any changes of products model and data,interpretation right reserved by Zhengyuan company

Appplication fields

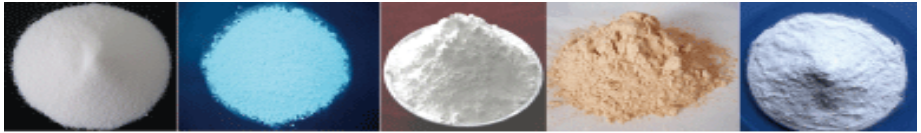

Minerals

Light calcium carbonate, ground calcium carbonate, kaolin, barite, attapulgite, talc, bentonite, mica, pyrophyllite, wollastonite, brucite, etc.

Chemical

Aluminum hydroxide, magnesium hydroxide, various flame retardants, precipitated barium sulfate, lithopone powder, epoxy powder, silica gel, white carbon black, carbon black, coal powder, titanium dioxide, fly ash, sericite, zinc oxide , Nanomaterials, etc.

Product Project cases